Navigating the Future: Key Industry Trends in Manufacturing for 2025

- Date

The manufacturing world is changing, and fast. As we look towards 2025, it’s clear that companies need to pay attention to some big shifts. Things like automation, smart technology, and how we deal with the environment are really shaking things up. Plus, customers want more personalized stuff, and finding good workers is getting harder. This article looks at the main industry trends in manufacturing you should know about to stay ahead.

Key Takeaways

- Automated, local factories are becoming more common to make supply chains stronger and cut costs. Think “dark factories” running themselves and smaller “microfactories” closer to customers.

- AI, especially generative AI, is changing how things are made. It’s helping optimize processes, making machines smarter, and even helping workers do their jobs better.

- Being eco-friendly and reusing materials is no longer optional. Companies are looking at circular economy ideas and using digital product passports to track items.

- Customers want products made just for them. This means manufacturers need to get better at customization, using things like 3D printing and data to understand what people want.

- There’s a big need for new skills in manufacturing. Companies are investing in training and figuring out how to get people to work with new tech, like AI, and keep them around.

The Rise of Autonomous and Localized Manufacturing

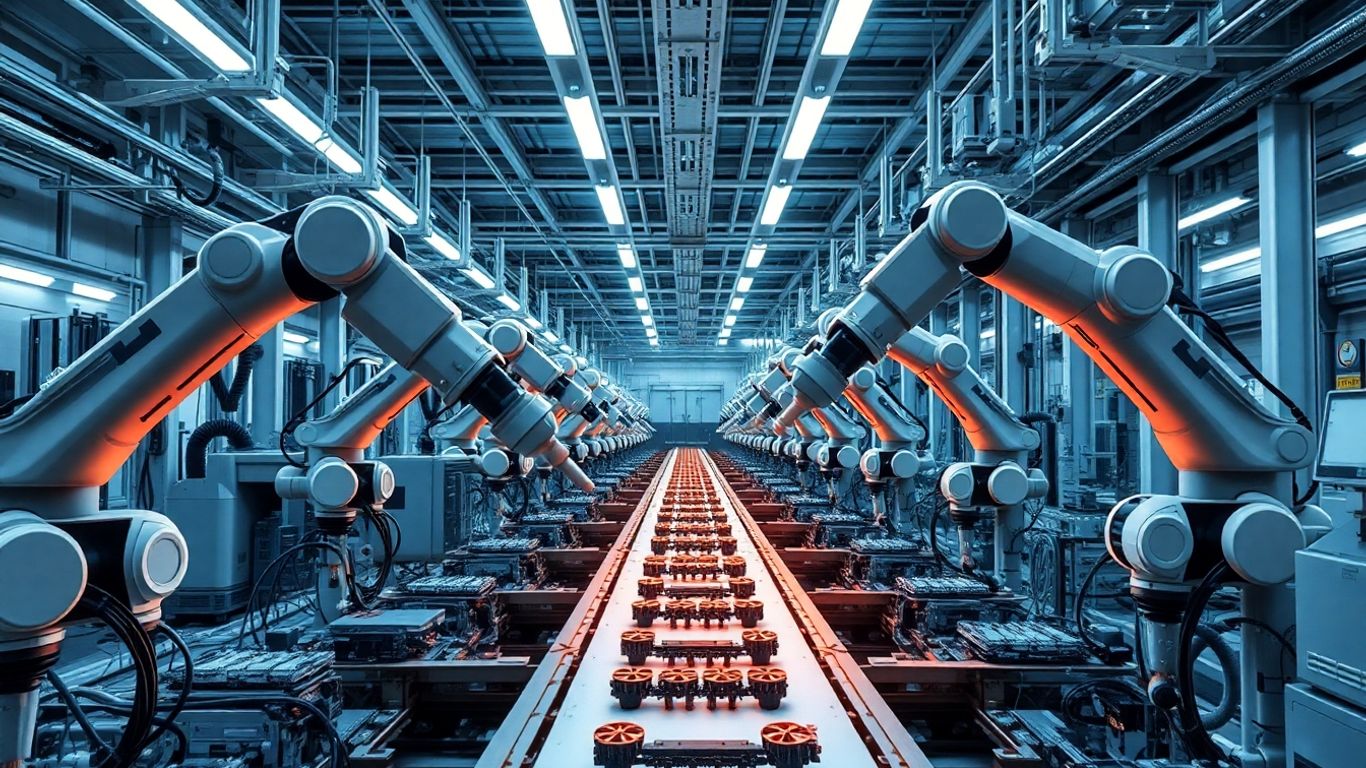

Manufacturing is really changing, and by 2025, we’re going to see some big shifts. Think about factories that can run themselves, even without lights on. That’s the idea behind ‘dark factories’. These places use robots and smart tech to keep things moving 24/7. Xiaomi, for example, has a factory that makes over 10 million phones a year, and it’s almost entirely automated. What’s even cooler is that the AI in these factories can actually figure out how to do things better over time, sort of like they’re teaching themselves.

Dark Factories: The Dawn of Fully Automated Operations

These fully automated facilities are becoming a reality. They rely on a mix of advanced robotics, AI, and the Internet of Things (IoT) to operate without human intervention. This means production can happen around the clock, boosting efficiency and allowing for quicker scaling of operations. It’s a big step towards a more streamlined manufacturing process.

Microfactories and Nearshoring for Supply Chain Resilience

We’re also seeing a move towards smaller, more localized factories, often called microfactories. This trend, along with bringing production closer to home (nearshoring), is a direct response to problems with long, complicated supply chains. Things like global events or bad weather can easily mess up deliveries when factories are too far away. By having smaller factories in more places, companies can react faster and keep products flowing even when there are disruptions. It’s all about making the supply chain tougher and less likely to break.

Additive Manufacturing’s Role in Agile Production

Additive manufacturing, which is basically 3D printing, is playing a bigger part in making production more flexible. It allows for quick changes to designs and the creation of custom parts without needing massive retooling. This speed is a game-changer for companies that need to adapt quickly to what customers want or to new market demands. It helps speed up how fast new ideas can be turned into actual products.

The push for more localized and automated manufacturing isn’t just about efficiency; it’s about building a more dependable system that can handle unexpected problems.

Here’s a quick look at how these trends are shaping up:

- Dark Factories: Aim for 24/7 operation with minimal human input.

- Microfactories: Smaller, localized production for quicker response times.

- Nearshoring: Bringing production closer to customers to reduce supply chain risks.

- Additive Manufacturing: Enabling faster customization and product development cycles.

Industrial AI and Generative AI Driving Transformation

It’s pretty clear that artificial intelligence, both the industrial kind and the newer generative AI, is really shaking things up in manufacturing. We’re not just talking about small tweaks anymore; these technologies are fundamentally changing how factories operate, how products are made, and even how people do their jobs.

AI-Powered Optimization Across Production Processes

Industrial AI is getting integrated into the core systems we already use, like those big ERP platforms and all the connected IoT devices on the factory floor. Think of it as giving your existing machinery and software a brain boost. This means better efficiency, less waste, and smarter decisions being made automatically. Early reports show manufacturers seeing big jumps in how quickly they can adapt to changes, how smoothly operations run, and how much better they can make choices based on real data. It’s not just theory; companies that are really leaning into this are already seeing tangible business improvements.

- Efficiency Gains: AI can fine-tune machine settings, manage energy use, and predict when equipment might need attention, all leading to smoother production.

- Quality Control: AI-powered vision systems can spot tiny defects that the human eye might miss, catching problems early.

- Resource Management: From scheduling staff to managing raw materials, AI can help optimize how everything is used.

The real game-changer here is moving from just reacting to problems to actually anticipating them. AI allows us to build systems that learn and adapt, making the entire production line more robust.

Generative AI’s Impact on Workforce Augmentation

Generative AI, or GenAI, is a bit different. While industrial AI focuses on optimizing existing processes, GenAI is more about creating new things and helping people do their jobs better. It can automate repetitive tasks, freeing up workers to focus on more complex problems or creative thinking. Imagine shopfloor workers having instant access to all the relevant data they need, presented in a way that helps them make faster, smarter decisions. This is leading to a kind of hybrid workforce where humans and AI work together, with AI handling the data crunching and humans providing the critical thinking and oversight.

- Skill Development: GenAI tools can help train workers faster by simulating scenarios or providing on-demand information.

- Design Assistance: Engineers can use GenAI to explore new product designs or material combinations much more quickly.

- Data Interpretation: GenAI can translate complex data sets into easy-to-understand insights for managers and frontline staff.

Leveraging AI for Predictive Maintenance and Quality Control

One of the most talked-about uses for AI in manufacturing is predictive maintenance. Instead of waiting for a machine to break down, AI algorithms analyze sensor data to predict when a failure is likely to happen. This means maintenance can be scheduled proactively, avoiding costly downtime and production delays. Similarly, AI is revolutionizing quality control. By analyzing vast amounts of data from production lines, AI can identify patterns that lead to defects, allowing manufacturers to correct issues before they become widespread. This not only improves product quality but also reduces scrap and rework.

- Reduced Downtime: Predicting equipment failures means maintenance can be done during planned stops.

- Improved Product Consistency: AI helps catch deviations from quality standards early in the process.

- Cost Savings: Less downtime and fewer defects directly translate to lower operational costs.

Sustainability and Circularity: A New Imperative

It’s becoming really clear that just making stuff isn’t enough anymore. Manufacturers are starting to see that being good to the planet isn’t just a nice-to-have, it’s a must-have for staying in business. This means thinking about how products are made, used, and then what happens to them afterward.

The Growing Importance of Circular Economy Principles

The old way of doing things – take, make, dispose – is out. The future is all about a circular economy. This means designing products so they can be easily taken apart, repaired, and reused. Think about companies like Scania, which is putting reused parts back into their heavy vehicles. They found it uses way less material and creates fewer emissions than making brand new parts. It’s a smart way to cut down on waste and be more efficient. We’re seeing more companies adopt these closed-loop systems, where old products become the raw materials for new ones. It’s a big shift, but one that makes a lot of sense for the long haul.

Digital Product Passports for Enhanced Transparency

How do you even know what’s in a product or where it’s been? That’s where Digital Product Passports (DPPs) come in. These are like a detailed history book for a product, often secured with blockchain. They can tell you about the environmental impact, what materials are used, and how it was made. Starting in 2027, batteries will be the first to get these mandatory passports, with other items like clothes following suit. This level of transparency helps everyone – from manufacturers to consumers – make better choices and makes recycling much simpler. It’s a big step towards a more honest and sustainable supply chain, and you can find more information on how AI is helping with supply chain optimization at AI in e-commerce .

AI’s Contribution to Sustainable Manufacturing Practices

Artificial intelligence is also playing a huge role here. AI can look at all the data from the factory floor and figure out how to use less energy or reduce material waste during production. It’s not just about being green; it often means saving money too. By optimizing processes, AI helps companies hit their environmental targets while also improving their bottom line. This integration of AI into sustainability efforts is what will really help manufacturing move towards a truly circular model in the coming years.

Here are some key areas where AI is making a difference:

- Optimizing energy consumption in real-time.

- Predicting and minimizing material waste.

- Improving the efficiency of recycling and remanufacturing processes.

- Tracking and managing the lifecycle of materials and components.

Hyperpersonalization and Evolving Business Models

Forget the one-size-fits-all approach; 2025 is all about making things just for you. Consumers are really starting to expect products tailored to their exact needs and wants. This isn’t just a nice-to-have anymore; it’s becoming a major driver for how manufacturers operate and what kind of businesses they build.

Meeting Consumer Demand for Customized Products

This shift means companies need to be way more flexible. They’re moving away from churning out massive quantities of the same item and instead focusing on producing smaller batches or even single items that are customized. Think about it: instead of picking a standard color for a car, you can now specify the exact shade, trim, and interior features you want, all without a massive price hike or long wait. This level of customization is becoming the new standard, and manufacturers that can deliver it will have a real edge. It’s about building relationships with customers by giving them exactly what they envision.

3D Printing Accelerating Personalization Cycles

One of the biggest game-changers here is additive manufacturing , or 3D printing. It’s not just for prototypes anymore. This technology allows for rapid design changes and quick production runs, making it perfect for custom orders. Need a specific medical implant? A unique piece of furniture? 3D printing can handle it. This speeds up the whole process from idea to finished product, letting manufacturers respond much faster to individual customer requests. It’s a key reason why hyperpersonalization is becoming a reality for more and more industries, from fashion to aerospace. We’re seeing this technology really take off, making custom goods more accessible than ever before.

Data Analytics for Deep Customer Understanding

So, how do manufacturers know what customers want? That’s where data analytics comes in. By looking at purchasing history, online behavior, and even social media trends, companies can get a really good picture of individual preferences. This information helps them not only offer personalized product suggestions but also to design new products that are likely to be popular. It’s about using data to anticipate needs before the customer even voices them. This kind of insight is what allows businesses to adapt their production lines and supply chains to meet these highly specific demands efficiently. It’s a whole new way of thinking about product development and customer service, all powered by information.

Here’s a look at how different sectors are adapting:

- Automotive: Custom interior options, unique paint finishes, and personalized tech packages.

- Fashion: Made-to-measure clothing, custom fabric choices, and personalized design elements.

- Consumer Electronics: Tailored software features, personalized device configurations, and unique accessory options.

The ability to gather and interpret customer data is no longer just about marketing; it’s about fundamentally changing how products are designed, produced, and delivered. Manufacturers are becoming more like bespoke tailors, crafting unique solutions for each client.

Addressing Workforce Challenges and Skill Gaps

It’s no secret that manufacturing is facing a bit of a people problem. We’ve got a lot of new tech coming online, but finding folks who know how to use it, or even just keeping the people we have, is proving tough. It feels like a constant juggling act.

Investing in Digital Tools and Workforce Training

Companies are realizing they can’t just expect people to magically know how to operate the latest machines. That’s why putting money into training programs is becoming super important. It’s not just about teaching someone how to push buttons; it’s about building a workforce that understands the whole digital ecosystem. Think about it:

- Upskilling Current Employees: Offering courses on new software, robotics, and data analysis helps existing staff adapt and grow with the company.

- Apprenticeship Programs: Partnering with schools or creating internal apprenticeships gives new hires hands-on experience with modern equipment.

- Digital Literacy Initiatives: Basic training on computers, tablets, and common manufacturing software can make a big difference for those new to the digital world.

Empowering Employees to Collaborate with AI

AI isn’t here to replace everyone, at least not yet. The real win is when people and AI work together. AI can handle the repetitive, data-heavy tasks, freeing up human workers to focus on things that require more thought and creativity. Imagine a worker getting real-time insights from an AI system right on their tablet, helping them make better decisions on the factory floor. That’s the kind of partnership we’re talking about.

The goal is to create a hybrid workforce where human ingenuity is amplified by artificial intelligence, leading to more efficient problem-solving and innovation.

Strategies for Talent Retention Amidst a Shifting Landscape

Keeping good people is just as hard as finding them. With a significant portion of the experienced workforce nearing retirement age, and many companies struggling to find workers with the right skills, retention strategies need a serious rethink. It’s not just about pay anymore. Companies need to look at the whole package:

- Career Path Development: Showing employees a clear route for advancement within the company.

- Flexible Work Arrangements: Where possible, offering some flexibility can make a big difference in work-life balance.

- Positive Work Culture: Creating an environment where employees feel valued, respected, and connected to the company’s mission.

The manufacturing sector needs to get creative to fill its talent pipeline and keep its experienced workers engaged. This means investing in people, embracing new ways of working with technology, and building a workplace that people actually want to stay in.

Cybersecurity and Digital Transformation Commitments

Mitigating Cybersecurity Threats in Connected Environments

Look, the manufacturing world is getting more connected by the day, right? Think smart factories, IoT devices talking to each other, all that jazz. It’s great for efficiency, but it also opens up a whole new playground for cyber threats. We’re talking about everything from ransomware locking up your production lines to data breaches exposing sensitive designs. Manufacturers absolutely need to treat cybersecurity not as an afterthought, but as a core part of their digital strategy. It’s not just about protecting data; it’s about keeping the actual lights on and the machines running.

Prioritizing Cloud Computing for Digital Transformation

So, where do you start with all this? Cloud computing is a big piece of the puzzle for digital transformation. Most factory bosses I talk to are looking at the cloud as the foundation for pretty much everything else they want to do digitally. It offers flexibility, scalability, and often, better security than trying to manage everything in-house. Plus, it makes it easier to integrate all those new AI tools and data analytics platforms we’re hearing so much about.

Here’s a quick look at why the cloud is so important:

- Scalability: Easily adjust computing power as your needs change.

- Accessibility: Access data and applications from anywhere.

- Cost-Effectiveness: Often reduces upfront hardware costs and ongoing maintenance.

- Security Updates: Cloud providers typically handle security patching and updates.

Strategic Technology Investments for Future-Proofing

It’s not enough to just want to transform; you have to actually put money into it. Many companies are starting their digital journeys, but the actual tech spending is still a bit low compared to overall budgets. We need to see more commitment here. Think about investing in things like robust data governance systems, secure cloud infrastructure, and tools that help your team work with new technologies. It’s about making smart choices now so you’re not left behind in a couple of years.

The reality is, if you’re not actively investing in securing your digital infrastructure and adopting new technologies, you’re essentially leaving the door open for problems. It’s a proactive game, not a reactive one.

What kind of investments are we talking about?

- Upgrading network security protocols.

- Implementing advanced threat detection systems.

- Investing in employee training for cybersecurity best practices.

- Adopting cloud-based security solutions.

Looking Ahead: What 2025 Means for Manufacturing

So, as we wrap up our look at 2025, it’s clear the manufacturing world is changing, and fast. We’ve talked about how AI and automation are becoming way more common, and how making things closer to home is a big deal now to avoid supply chain headaches. Plus, being good to the planet through circular practices isn’t just a nice idea anymore; it’s becoming a must-do. It might seem like a lot, and honestly, some companies are still figuring out where to start. But the ones that jump in now, embracing these new ways of working and investing in their people and tech, are the ones that will likely do well. It’s about adapting, plain and simple. The future is here, and it’s time to get on board.

Frequently Asked Questions

What are “dark factories” and why are they important?

Dark factories are like super-smart factories that can run all by themselves, even without lights on. They use robots and computers to do all the work, 24/7. This makes them really efficient and able to make a lot of stuff very quickly.

What does “nearshoring” mean for manufacturing?

Nearshoring means making products closer to where people will buy them, instead of far away. This helps companies avoid problems with shipping and makes their supply chains stronger, like having backup plans if something goes wrong.

How is AI changing how factories work?

AI, which is like making computers think and learn, is helping factories work better. It can figure out the best ways to make things, predict when machines might break, and help check if products are good quality, making everything run smoother.

What is the “circular economy” in manufacturing?

The circular economy is about using things again and again instead of throwing them away. In manufacturing, it means designing products so they can be reused, fixed, or recycled easily, which is better for the planet and uses fewer resources.

Why is making products unique to each customer becoming more common?

People want products that are special just for them. So, companies are using technology like AI and 3D printing to make it easier and faster to create custom items, giving customers exactly what they want.

What’s the biggest challenge for factory workers in the future?

Many factory workers need to learn new skills because of all the new technology, like AI and robots. Companies are working on training programs to help them learn these new skills so they can work alongside these new tools and keep their jobs.